Scientific Program

You can update your brief biography and profile picture on the [My Profile] page.

- Session TrackBiomaterials processing and biofabrication

- Session TitleMicrofabrication techniques for vascularization of tissue engineered constructs

- Session CodeSP-T02-0326

- Date & Time / RoomMay 31 (Fri) 9:30~11:00 / Room 323

- Organizer

-

Gulden Camci-Unal (University of Massachusetts Lowell, USA)

- Chair

-

Gulden Camci-Unal (University of Massachusetts Lowell, USA)

Syam Nukavarapu (University of Connecticut, USA)

- Keynote Speaker

-

9:30~9:55 : 3D EXTRUDABLE HYBRID BIO(MATERIAL) INK FORMULATION: PROCESS SCIENCE AND BIOCOMPATIBILITY Bikramjit Basu (Indian Institute of Science, Bangalore, India)

- Invited Speaker

-

9:55~10:10 : The Integration of Tailored Peptides into Bioinks via Photo Induced Crosslinking of Unmodified Proteins Yeong-Jin Choi (Korea Institute of Materials Science, Korea, Republic of)

10:10~10:25 : Application of advanced, various tissue-specific bioinks for engineering vascularized in vitro multiorgan/disease constructs Jungbin Yoon (POSTECH, Korea, Republic of)

- Oral Presenter

-

10:25~10:35 : The use of proteomics in extrusion and volumetric-based biofabrication for optimal bone regeneration Laurens Parmentier (Ghent University, Belgium)

10:35~10:45 : Coaxial 3D Bioprinting of Blood Vessel Grafts and Vascular Disease Models Ge Gao (School of Medical Technology, Beijing Institute of Technology, China)

10:45~10:55 : Mimicking the vascularized cortical bone: an advanced in vitro osteon model to study bone (patho)physiological conditions clarissa tomasina (Maastricht University, Netherlands)

- Session TrackBiomaterials processing and biofabrication

- Session TitleNovel and multiple fabrication processes

- Session CodeSP-T02-0090

- Date & Time / RoomMay 27 (Mon) 13:00~14:30 / Room 325-CD

- Organizer

-

Hee-Gyeong Yi (Dept. of Convergence Biosystems Engineering/Chonnam National University, Korea, Republic of)

- Chair

-

Michiya Matsusaki (Department of Applied Chemistry, Osaka University, Japan)

Hee-Gyeong Yi (Dept. of Convergence Biosystems Engineering, Chonnam National University, Korea, Republic of)

- Keynote Speaker

-

Tan Lay Poh (School of Materials Science & Engineering, Nanyang Technological University (NTU), Singapore)

- Invited Speaker

-

13:25~13:40 : Machine learning-assisted optimization of printability in extrusion-based bioprinting Seung Yun Nam (Pukyong National University, Korea, Republic of)

- Oral Presenter

-

13:40~13:50 : 3D Bio-Screen Printing for the Industrial Production of Textured Cultivated Meat Precursors Robin Maatz (Technical University of Darmstadt, Germany)

13:50~14:00 : Formulation and bioprinting of xanthan gum/iron hydrogels with tunable stiffness for long-term carrying of unstable and low-viscosity proteins Monize Caiado Decarli (1- University of Maastricht and 2- University Medical Center Groningen, Netherlands)

14:00~14:10 : A hydrogel blend for immobilizing carrot callus with microextrusion bioprinting Susmita Ghosh (Chonnam National University, Korea, Republic of)

14:10~14:20 : Days- to weeks-long perfusion of human-scale artificial pancreatic tissues created using sacrificial embedded writing into alginate Brenden Moeun (McGill University, Canada)

14:20~14:30 : 3D printing of primary adipose tissue with silk scaffold for volumetric soft tissue reconstruction Wonwoo Jeong (Wake Forest Institute for Regenerative Medicine, USA)

- Session TrackBiomaterials processing and biofabrication

- Session TitleFrontiers in Biofabrication Technologies

- Session CodeSP-T02-0123

- Date & Time / RoomMay 28 (Tue) 16:30~18:00 / Room 325-CD

- Organizer

-

Lorenzo Moroni (Maastricht University, Netherlands)

- Chair

-

Lorenzo Moroni (Maastricht University, Netherlands)

Koichi Nakayama (Saga University, Japan)

- Keynote Speaker

-

16:30~16:55 : Dynamic biomaterials to enable biofabrication of personalized tissue mimics Sarah Heilshorn (Stanford University, USA)

- Invited Speaker

-

16:55~17:10 : Matryoshka-inspired Biological Constructs to mimic skeletal niche for osteochondral regeneration Lorenzo Moroni (Maastricht University, Netherlands)

17:10~17:25 : Inventing for scalability: creating a formulation library to bioprint any human tissue from one tuneable synthetic biomaterial foundation Martin Engel (Inventia Life Science, Australia)

17:25~17:40 : Tissue regenerative medicine research using 3D bioprinters and bioinks Dong Hyuk Lee (Gachon University, CleCell Co., Ltd., Korea, Republic of)

- Oral Presenter

-

17:40~17:50 : Bioinspired scaffolds for the regeneration of the temporomandibular joint Joanna BABILOTTE (MERLN Institute, Netherlands)

- Session TrackBiomaterials processing and biofabrication

- Session TitleMulti-layer biomaterials: emerging applications

- Session CodeSP-T02-0126

- Date & Time / RoomMay 30 (Thu) 16:30~18:00 / Room 320-B

- Organizer

-

Wei Li (Texas Tech University, USA)

- Chair

-

Wei Li (Texas Tech University, USA)

Michiya Matsusaki (Osaka University, Japan)

- Keynote Speaker

-

16:30~16:55 : Development of layer-by-layer films for regenerative medicine and cell signalling studies: application to bone tissue engineering Catherine Picart (French Alternative Energies and Atomic Energy Commission, France)

- Invited Speaker

-

16:55~17:10 : Building Bioactivity into Slippery Liquid-Infused Porous Surfaces David Lynn (University of Wisconsin Madison, USA)

17:10~17:25 : Tissue-interfaced electronics with multi-layered structure Toshinori Fujie (Tokyo Institute of Technology, Japan)

- Oral Presenter

-

17:25~17:35 : 4D printed scaffolds for tissue repair and regeneration Kaushik Chatterjee (Indian Institute of Science, India)

17:35~17:45 :

SURFACE FUNCTIONALIZATION OF TITANIUM IMPLANTS FOR BIOLOGICALLY ACTIVE SURFACES: ALTERNATING CURRENT ELECTROPHORETIC DEPOSITION AND ATMOSPHERIC PRESSURE PLASMA TECHNOLOGYMerve Kübra Aktan (Katholieke Universiteit Leuven, Belgium)17:45~17:55 : Development of the core, titanium based material and polymer coating for the needs of individualized regenerative medical applications Ewa Rzad (Lukasiewicz Research Network – Krakow Institute of Technology, Poland)

17:55~18:05 : 3D printing of diamond for an iImproved hard tissue bio-interface Kate Fox (RMIT, Australia)

- Session TrackBiomaterials processing and biofabrication

- Session TitleBiofunctional material and this use in medical device application

- Session CodeSP-T02-0389

- Date & Time / RoomMay 27 (Mon) 14:40~16:10 / Room 325-CD

- Organizer

-

Jayden Park (Evonik Korea Ltd., Korea, Republic of)

- Chair

-

Hyuk Sang Yoo (Kangwon National University, Korea, Republic of)

Jake Cho (Evonik Korea Ltd., Korea, Republic of)

- Keynote Speaker

-

14:40~15:05 : Innovating biomaterials for clinical use Andreas Karau (Evonik Operations GmbH, Germany)

- Invited Speaker

-

15:05~15:20 : Advancements in 3D-printed bioresorbable medical devices, bio-surgical solutions, and 3D bioprinting Heidy Cruz (T&R Biofab, Korea, Republic of)

15:20~15:35 : Artificial Intelligence Convergence Hyper-personalized SKIN Regeneration 3D Bioprinting Technology Jeehee Kim (ROKIT Healthcare, Inc., Korea, Republic of)

15:35~15:50 : Biomimetic and biosynthetic building blocks as platform technology in 3D-bioprinting Andreas Blaeser (Technical University of Darmstadt, Institute for Biomedical printing technology, Germany)

- Oral Presenter

-

15:50~16:00 : Minimalistic strategies for designing new biomaterial solutions: From thin platforms to living materials Tiago Correia (University of Aveiro, Portugal)

16:00~16:10 : Bioinspired alginate-based bioinks to fabricate chemomechanically relevant disease models of hepatic steatosis Giuseppe Guagliano (Polytechnic University of Milan, Italy)

- Session TrackBiomaterials processing and biofabrication

- Session TitleBiofabrication strategies to engineer complex tissues

- Session CodeSP-T02-0145

- Date & Time / RoomMay 28 (Tue) 9:30~11:00 / Room 325-AB

- Organizer

-

Lesley Chow (Lehigh University, USA)

- Chair

-

Lesley Chow (Lehigh University, USA)

Liliang Ouyang (Tsinghua University, China)

- Keynote Speaker

-

9:30~9:55 : Light-based Biofabrication of Mammary Tissue Marcy Zenobi-Wong (ETH Zurich, Switzerland)

- Invited Speaker

-

9:55~10:10 : 3D bioprinting of transplantable tracheas Yong He (Zhejiang University, China)

10:10~10:25 : Recreating tendon structure and biomechanical environment using magnetic 3D Bioprinting Manuela Gomes (3B's Research Group, University of Minho, Portugal)

- Oral Presenter

-

10:25~10:35 : 3D Bioprinting of Perfusable Networks Using an Interfacial Diffusant Strategy Betty Cai (Stanford University, USA)

10:45~10:55 : 3D-Printing of Scaffolds with Surface Micropatterns For Oriented Tissue Regeneration Yonghui Ding (Worcester Polytechnic Institute, USA)

- Session TrackBiomaterials processing and biofabrication

- Session TitleConverged Technologies towards Tissue Biofabrication

- Session CodeSP-T02-0156

- Date & Time / RoomMay 28 (Tue) 13:40~15:10 / Room 325-CD

- Organizer

-

Y. Shrike Zhang (Harvard Medical School, USA)

- Chair

-

Y. Shrike Zhang (Harvard Medical School, USA)

Jinah Jang (Pohang University of Science and Technology, Korea, Republic of)

- Keynote Speaker

-

13:40~14:05 : Biointerface fiber technology from electrospinning to in situ fibre printing Yan Yan Shery Huang (University of Cambridge, United Kingdom)

- Invited Speaker

-

14:05~14:20 : Enabling bioinks with tunable mechanical and topological cues for 3D cell culture and vascularization Liliang Ouyang (Tsinghua University, China)

14:20~14:35 : Convergence of Biofabrication Approaches for the Generation of Small Diameter Vascular Tissue Models Tomasz Jungst (University of Würzburg, Germany)

- Oral Presenter

-

14:35~14:45 : Advanced materials and biofabrication technologies to design in vitro central nervous system models Chiara Tonda Turo (Politecnico di Torino, Italy)

14:45~14:55 : Mechanical Behavior of 3D Printed Continuous Carbon Fiber Reinforced PEKK Composites for Trauma Plate Applications Steven Kurtz (Drexel University, USA)

- Session TrackBiomaterials processing and biofabrication

- Session TitleFostering international multidisciplinary collaboration in biomaterials research: Australasia- Germany case study (sponsored by Maverick)

- Session CodeSP-T02-0201

- Date & Time / RoomMay 31 (Fri) 11:20~12:50 / Room 321-B

- Organizer

-

Khoon Lim (University of Sydney, Australia)

- Chair

-

Michael Gelinsky (Technische Universität Dresden, Germany)

Jelena Rnjak-Kovacina (University of New South Wales, Australia)

- Keynote Speaker

-

Juergen Groll (University of Würzburg, Germany)

- Invited Speaker

-

11:45~12:00 : Structure, stimulation, and close interactions: keys to enhancing outcomes from international and multidisciplinary tissue engineering research Andrea O'Connor (University of Melbourne, Australia)

12:00~12:15 : What are the factors that drive effective international collaborations? Helmut Thissen (Commonwealth Scientific and Industrial Research Organisation, Australia)

- Oral Presenter

-

12:15~12:25 : Bioprinting Corneal Tissue Mimics In Situ using Visible-Light Photopolymerizable Bioinks Daniela Duarte Campos (Heidelberg University, Germany)

12:25~12:35 : Dual-stage crosslinking hyaluronic acid-based bioinks for bioprinting advanced cartilaginous tissues Joerg Tessmar (University of Würzburg, Germany)

12:35~12:45 : Multi-architectural scaffold design unlocking clinically relevant cardiac patch attachment Johannes Braig (University Hospital of Wuerzburg, Germany)

- Session TrackBiomaterials processing and biofabrication

- Session TitleInjectable Hydrogels For Regenerative Medicine

- Session CodeSP-T02-0250

- Date & Time / RoomMay 31 (Fri) 9:30~11:00 / Room 325-CD

- Organizer

-

Arghya Paul (The University of Western Ontario, Canada)

- Chair

-

Arghya Paul (The University of Western Ontario, Canada)

Akhilesh Gaharwar (Texas A&M University, USA)

- Keynote Speaker

-

9:30~9:55 : Bioinspired immunomodulatory materials for regenerative medicine Milica Radisic (University of Toronto, Canada)

- Invited Speaker

-

9:55~10:10 : Dynamic covalently-crosslinked zwitterionic injectable hydrogels enabling functional muscle repair and bioprinting of tissue mimics Todd Hoare (McMaster University, Canada)

10:10~10:25 : Immediately injectable dental stem cells-laden chitosan/hyaluronic acid hydrogel for vascularized bone tissue regeneration Sang Jin Lee (The University of Hong Kong, Hong Kong SAR, China)

10:25~10:40 : 3D printed stretchable skin scaffold for human joint Jin Woo Lee (Gachon University, Korea, Republic of)

- Oral Presenter

-

10:40~10:50 : Time dependent Alginate Dialdehyde-Gelatin bioinks for cardiac regeneration Elena Marcello (Politecnico di Torino, Italy)

10:50~11:00 : Photo-crosslinked Mucin Bioink for 3D Bioprinting and Soft Tissue Engineering Sruthi C S (Indian Institute of Science, India)

- Session TrackBiomaterials processing and biofabrication

- Session TitleOpen-source and low-cost technologies for advanced biomaterials fabrication

- Session CodeSP-T02-0359

- Date & Time / RoomMay 30 (Thu) 9:30~11:00 / Room 321-A

- Organizer

-

Adam Feinberg (Carnegie Mellon University, USA)

- Chair

-

Adam Feinberg (Carnegie Mellon University, USA)

Mark Skylar-Scott (Stanford University, USA)

- Keynote Speaker

-

9:30~9:55 : Tissue Assembloids via Low-Cost Biofabrication Setups Yan Yan Shery Huang (University of Cambridge, United Kingdom)

- Invited Speaker

-

9:55~10:10 : Open-source low-cost 3D bioprinters for advanced biomanufacturing Daniel Shiwarski (University of Pittsburgh, USA)

10:10~10:25 : High-precision 3D cell spheroid printing technology to produce engineered tissue with enhanced functionality Hyun-Wook Kang (Ulsan National Institute of Science and Technology, Korea, Republic of)

- Oral Presenter

-

10:25~10:35 : The MEWron: Open-source melt electrowriting Simon Luposchainsky (Kyoto Institute of Technology, Japan)

10:35~10:45 : Effects of Painting Parameters on Tribological Properties in 3D Printed Parts Okan Gul (kocaeli university, Türkiye)

- Session TrackBiomaterials processing and biofabrication

- Session TitleAdditive manufacturing of biomaterials

- Session CodeSP-T02-0142

- Date & Time / RoomMay 30 (Thu) 13:40~15:10 / Room 325-CD

- Organizer

-

Masaya Yamamoto (Tohoku University, Japan)

- Chair

-

Masaya Yamamoto (Tohoku University, Japan)

Miho Nakamura (University of Turku, Finland)

- Keynote Speaker

-

13:40~14:05 : Development of novel spinal fusion spacer fabricated by metal additive manufacturing focusing on the orientation of bone tissue architecture Takayoshi Nakano (Osaka University, Japan)

- Invited Speaker

-

14:05~14:20 : Novel Support-less Bioceramics Additive Manufacturing Process in a Hydrogel Bath Hui-suk Yun (Korea Institute of Materials Science, Korea, Republic of)

Artemis Stamboulis (University of Birmingham, United Kingdom)

- Oral Presenter

-

14:35~14:45 : Bioactive Ceramic for Immunotherapy: Effect of ionic composition on macrophage anti-inflammatory phenotypic expression Miho Nakamura (University of Turku/Tokyo Medical and Dental University, Finland)

14:45~14:55 : Modulated stem cell differentiation by 3D sandwich cell culture using stiffness-tunable hydrogels Masaya Yamamoto (Tohoku University, Japan)

14:55~15:05 : 3D printed Bioglass scaffolds with gyroid architecture for bone regeneration using DLP Meryem Lamari (Imperial College London, United Kingdom)

- Session TrackBiomaterials processing and biofabrication

- Session Title3D Printing and Biofabrication in TERM, on the way to translation

- Session CodeSP-T02-0154

- Date & Time / RoomMay 29 (Wed) 16:30~18:00 / Room 323

- Organizer

-

Aleksandr Ovsianikov (TU Wien [Technische Universität Wien], Austria)

- Chair

-

Aleksandr Ovsianikov (TU Wien [Technische Universitaet Wien], Austria)

Tim Woodfield (University of Otago, New Zealand)

- Keynote Speaker

-

Scott Hollister (Georgia Institute of Technology and Emory University, USA)

- Invited Speaker

-

Jinah Jang (Pohang University of Science and Technology, Korea, Republic of)

17:10~17:25 : Bioengineering an Ovarian Microenvironment Informed by the Human Ovary BioMolecular Atlas Monica Laronda (Northwestern University, USA)

- Oral Presenter

-

17:25~17:35 : 3D Bio-printing for Tissue Engineering Application Binbin Sun (Donghua University, China)

17:35~17:45 : Alveolar bone repair of rhesus monkeys by using BMP-2 gene and MSCs loaded three-dimensional printed bioglass scaffold Weikang Xu (Institute of biological and Medical Engineering, Guangdong Acamedy of Sciences, China)

17:45~17:55 : Additive manufactured porous titanium with gradient structure balancing bone ingrowth and antibacterial activity: evaluation of in vitro antibacterial activity Seiji Yamaguchi (Chubu University, Japan)

- Session TrackBiomaterials processing and biofabrication

- Session TitleVolumetric tissue printing

- Session CodeSP-T02-0267

- Date & Time / RoomMay 27 (Mon) 16:30~18:00 / Room 325-CD

- Organizer

-

Jinah Jang (Pohang University of Science and Technology, Korea, Republic of)

- Chair

-

Riccardo Levato (University Medical Center Utrecht, Netherlands)

Jinah Jang (Pohang University of Science and Technology, Korea, Republic of)

- Keynote Speaker

-

16:30~16:55 : Filamented Light (FLight) Biofabrication of Tendons and Muscle Marcy Zenobi-Wong (ETH Zurich, Switzerland)

- Invited Speaker

-

16:55~17:10 : Volumetric bioprinting: from the first development to advanced imaging-guided and multi-technology biofabrication Riccardo Levato (University Medical Center Utrecht, Netherlands)

- Oral Presenter

-

17:10~17:20 : Stable and Homogeneous SPION-infused Photo-Resins for 3D-Printing Magnetic Hydrogels Ali Mohammed (Royal College of Art, Imperial College London, United Kingdom)

17:20~17:30 : Melt electrowriting and its applications in biofabrication for the generation of synthetic tubular constructs with defined mechanical characteristics Michael Bartolf-Kopp (Universitätsklinikum Würzburg, Germany)

17:30~17:40 : Development of Efficient Photoinitiating Systems for 3D Printing Pu Xiao (Chinese Academy of Sciences, China)

17:40~17:50 : Visible Light-Induced 3D Co-axial Bioprinting of 3D Biomimetic Liver-like Tissue Module with Patterned Vascular Structures for Volumetric Tissue Reconstruction Daekeun Kim (Pohang University of Science and Technology, Korea, Republic of)

17:50~18:00 : Fibrillogenesis-inhibited collagen-based photoclick resins enable facile volumetric biofabrication of multi-cellular tissues Parth Chansoria (ETH Zurich, Switzerland)

- Session TrackBiomaterials processing and biofabrication

- Session TitleCreating 3D architectures to facilitate organ regeneration

- Session CodeSP-T02-0076

- Date & Time / RoomMay 31 (Fri) 11:20~12:50 / Room 320-B

- Organizer

-

Qi Gu (Beijing Institute for Stem Cell and Regenerative Medicine, China)

- Chair

-

Qi Gu (Beijing Institute for Stem Cell and Regenerative Medicine, China)

- Keynote Speaker

-

TBD (, )

- Invited Speaker

-

11:45~12:00 : Exploring controlled cell movement to create engineered organs with natural properties Qi Gu (Beijing Institute for Stem Cell and Regenerative Medicine, China)

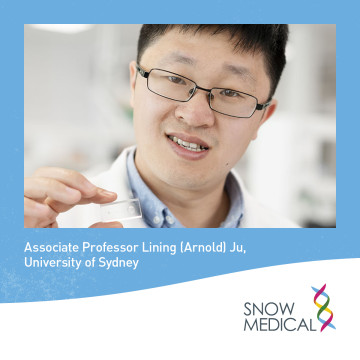

12:00~12:15 : Developing Personalized Vein-Chips for Enhanced Cerebral Venous Sinus Thrombosis Diagnosis using a Movable Type Manufacturing Technique Arnold Lining Ju (University of Sydney, Australia)

- Oral Presenter

-

12:15~12:25 : Designing gradient bioinks for the musculoskeletal interface Lesthuruge De Silva (Deakin University, Australia)

12:25~12:35 : Bioprinting-assisted Tissue Assembly for Studying Cardiac Pathophysiology Dong Gyu Hwang (POSTECH, Korea, Republic of)

12:35~12:45 : Gastric-cancer-on-a-chip for predicting precision anti-cancer therapy. Jisoo Kim (POSTECH, Korea, Republic of)

- Session TrackBiomaterials processing and biofabrication

- Session TitleBiofabrication in Suspensions Media for Tissue Engineering and In Vitro Modeling

- Session CodeSP-T02-0356

- Date & Time / RoomMay 29 (Wed) 13:40~15:10 / Room 325-CD

- Organizer

-

Manuela Gomes (3B's Research Group, University of Minho, Portugal)

- Chair

-

Manuela Gomes (3B's Research Group, University of Minho, Portugal)

Andrew Daly (National University of Ireland Galway, Ireland)

- Keynote Speaker

-

13:40~14:05 : Advances in suspension bath printing to control the organization of cells and materials Jason Burdick (University of Colorado Boulder, USA)

- Invited Speaker

-

14:05~14:20 : Biomanufacturing in vitro tendon microenvironments in suspension Rui M. A. Domingues (3B's Research Group, University of Minho, Portugal)

14:20~14:35 : Bioprinting models of early organ morphogenesis using cell-responsive hydrogels Andrew Daly (National University of Ireland Galway, Ireland)

- Oral Presenter

-

14:35~14:45 : Enhanced angiogenic response of bioprinted vessel-like structures enriched with platelet rich plasma Maria Chatzinikolaidou (Foundation for Research and Technology Hellas (FORTH) Institute of Electronic Structure and Laser 100, N. Plastira str. Vassilika Vouton GR-70013 Heraklion, Greece VAT 090101655., Greece)

14:45~14:55 : Support baths to float your boat: 3D printing of low-viscosity PEG/graphene oxide inks to engineer vascular grafts Helena Ferreira (i3S - Instituto de Investigação e Inovação em Saúde, Universidade do Porto, Portugal)

14:55~15:10 : Hydrogel microfibers as a granular material and its application as an ink or support bath in bioprinting

Chris Highley (University of Virginia, USA)

- Session TrackBiomaterials processing and biofabrication

- Session TitleBio-hybrid tissue printing

- Session CodeSP-T02-0112

- Date & Time / RoomMay 28 (Tue) 9:30~11:00 / Room 325-CD

- Organizer

-

Hyun-Wook Kang (Ulsan National Institute of Science and Technology, Korea, Republic of)

- Chair

-

Aleksandr Ovsianikov (Technische Universität Wien, Austria)

Hyun-Wook Kang (Ulsan National Institute of Science and Technology, Korea, Republic of)

- Keynote Speaker

-

9:30~9:55 : Scaffold-free Bio-3D Printing for Solid organ fabrication Koichi Nakayama (Saga University, Japan)

- Invited Speaker

-

9:55~10:10 : 3D Bioprinting Strategies for Building Human Body Parts Sang Jin Lee (Wake Forest School of Medicine, USA)

10:10~10:25 : Scaffolded Spheroids – A New Strategy for Cartilage and Bone Tissue Engineering Aleksandr Ovsianikov (Technische Universität Wien, Austria)

10:25~10:40 : Non-adjacent wireless electrotherapy for tissue repair by a bioresorbable fully soft triboelectric nanogenerator Zhengwei You (Donghua University, China)

- Oral Presenter

-

10:40~10:50 : 3D bioprinting hydrogel of biomimetic ECM for engineered brain-like constructs fabrication Yu Song (Tsinghua University, China)

10:50~11:00 : Voxel-by-voxel multi-material 3D printing for creating biomimetic interfaces Mohammad J. Mirzaali (TU Delft, Netherlands)

- Session TrackBiomaterials processing and biofabrication

- Session TitleCell Encapsulation and 3D Digital Assembly for Basic and Applied Biomedicine

- Session CodeSP-T02-0245

- Date & Time / RoomMay 31 (Fri) 11:20~12:50 / Room 325-CD

- Organizer

-

Liheng Cai (University of Virginia, USA)

- Chair

-

Liheng Cai (University of Virginia, USA)

Jae-Won Shin (University of Illinois at Chicago, USA)

- Keynote Speaker

-

David Weitz (Harvard University, USA)

- Invited Speaker

-

11:45~12:00 : Scaling 3D Bioprinting for Whole Organ Engineering Mark Skylar-Scott (Stanford University, USA)

12:00~12:15 : Voxelated Bioprinting: Digital Assembly of Viscoelastic Bio-ink Droplets Liheng Cai (University of Virginia, USA)

- Oral Presenter

-

12:15~12:25 : Programmable collective self-assembly of cells in heterogeneous space via magneto-Archimedes effect Tanchen Ren (Zhejiang University, China)

12:25~12:35 : Development of a Biohybrid 3D-Printed Muscular Tissue-Sensor Platform for Excitation–Contraction Coupling Monitoring Uijung Yong (Pohang University of Science and Technology, Korea, Republic of)

12:35~12:45 : Development of drug-eluting contact lenses via 3D bioprinting to support corneal healing Mario Milazzo (Università di Pisa, Italy)

- Session TrackBiomaterials processing and biofabrication

- Session TitleExploring the Frontiers of Micro-Nano Surface Engineering of Biomaterials

- Session CodeSP-T02-0284

- Date & Time / RoomMay 30 (Thu) 16:30~18:00 / Room 325-CD

- Organizer

-

Ketul Popat (Colorado State University, USA)

- Chair

-

Ketul Popat (Colorado State University, USA)

Geetha Manivasagam (Vellore Institute of Technology, India)

- Keynote Speaker

-

16:30~16:55 : Nanotextural engineering of calcium phosphate bone grafts: interaction with proteins, cells and tissues Maria-Pau Ginebra (Universitat Politècnica de Catalunya (UPC), Spain)

- Invited Speaker

-

16:55~17:10 : Cold Atmospheric Plasma Patch‐Mediated Skin Anti‐Inflammatory Therapy Seunghun Lee (Korea Institute of Materials Science, Korea, Republic of)

17:10~17:25 : Nanofiber membranes for reconstruction of tissue barriers and generation of uniform organoids Dong Sung Kim (POSTECH, Korea, Republic of)

- Oral Presenter

-

17:25~17:35 : Two-dimensional architectures-transformed drugless conformational nanoarchitectonics for light-augmented nanocatalytic chemodynamic therapy Ranjith Kumar Kankala (Huaqiao University, China)

17:35~17:45 : Laser surface patterning of stainless steel for improvement of blood compatibility Yang Liu (Loughborough University, United Kingdom)

17:45~17:55 : Development of 3D-printed antimicrobial Si3N4-PEEK cervical spine cages: phase I Ryan Bock (SINTX Technologies, Inc., USA)

- Session TrackBiomaterials processing and biofabrication

- Session TitleMelt Electrowriting of Scaffolds

- Session CodeSP-T02-0315

- Date & Time / RoomMay 30 (Thu) 13:40~15:10 / Room 320-B

- Organizer

-

Paul Dalton (University of Oregon, USA)

- Chair

-

Paul Dalton (University of Oregon, USA)

Małgorzata Włodarczyk-Biegun (Silesian University of Technology, Poland)

- Keynote Speaker

-

13:40~14:05 : MEW, Hydrogels, and BMP-2 Converge to Orchestrate Membrane Guided Bone Regeneration Dietmar Hutmacher (Max Planck Queensland Center, Queensland University of Technology, Australia)

- Invited Speaker

-

Naomi Paxton (University of Oregon, USA)

14:20~14:35 : Melt Electrowriting to assist regeneration of injured gradient tissues Małgorzata Włodarczyk-Biegun (Silesian University of Technology, Poland)

- Oral Presenter

-

14:35~14:45 : Development of smart nanofibers as a wearable blood purification filter Makoto Sasaki (National Institute for Materials Science, Japan)

14:45~14:55 : Piezoelectric nanoyarns to advance self-powered acoustic cochlear transducers Bahareh Azimi (University of Pisa, Italy)

14:55~15:05 : Ultrasonic levitated electrospinning Haoyu Wang (UCL, United Kingdom)

- Session TrackBiomaterials processing and biofabrication

- Session TitleMicro/nano-patterning

- Session CodeSP-T02-0135

- Date & Time / RoomMay 29 (Wed) 9:30~11:00 / Room 325-CD

- Organizer

-

Dong Sung Kim (POSTECH, Korea, Republic of)

- Chair

-

Dong Sung Kim (POSTECH, Korea, Republic of)

Jennifer H. Shin (KAIST, Korea, Republic of)

- Keynote Speaker

-

9:30~9:55 : Hair regenerative medicine using tissue engineering approaches Junji Fukuda (Yokohama National University (YNU), Japan)

- Invited Speaker

-

9:55~10:10 : Role of ECM Microstructures in the Dynamics of the Tumor Microenvironment Jennifer H. Shin (KAIST, Korea, Republic of)

10:10~10:25 : Understanding matrix remodeling-directed lineage specification through microfluidic encapsulation of single stem cells Jae-Won Shin (University of Illinois at Chicago, USA)

- Oral Presenter

-

10:25~10:35 : Shape-specific microcomposites induce osteogenic differentiation in bottom-up engineered microtissue Ke Song (Maastricht University, Netherlands)

10:35~10:45 : Vanillin-based functionalization strategy to construct multifunctional microspheres for treating inflammation and regenerating intervertebral disc zhuang zhu (Soochow University, China)

10:45~10:55 : In situ culture of the unculturable human gastrointestinal bacteria Sydney Wheatley (École de technologie supérieure, Canada)

1

1